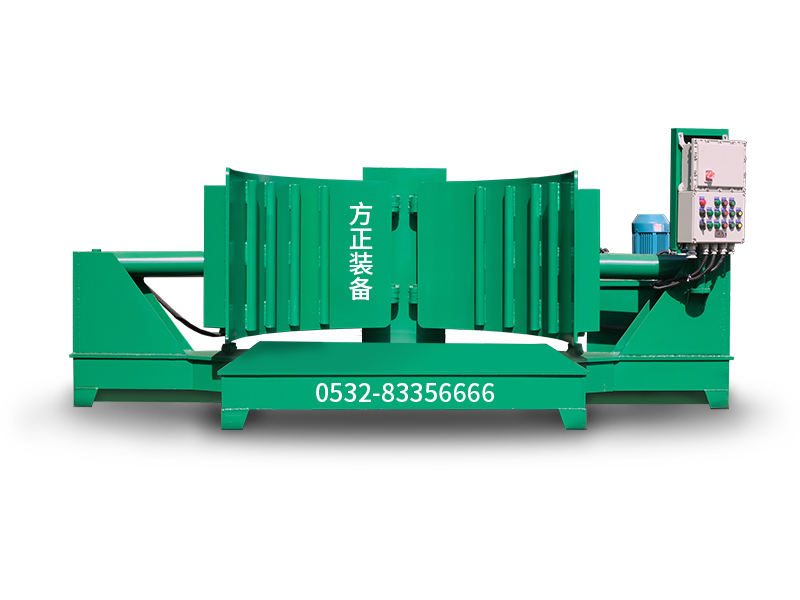

With the popularization of electronic metering ingredients in compound fertilizer production, raw material suppliers are increasingly using ton packaging for ammonium chloride and ammonium phosphate. However, the agglomeration of ton packaging raw materials affects electronic metering ingredients and must be crushed and loosened first. The FZDB-1000 ton bag material loosening machine was developed to solve this problem. Adopting electronic remote control and hydraulic technology. It has the characteristics of simple structure, easy operation, and good extrusion effect

model:

Size: 4150 * 2050 * 1520mm

Power: 12 packs/hour

Efficiency: 7.5KW

Weight: 3000KG

Introduction:

With the popularization of electronic metering ingredients in compound fertilizer production, raw material suppliers are increasingly using ton packaging for ammonium chloride and ammonium phosphate. However, the agglomeration of ton packaging raw materials affects electronic metering ingredients and must be crushed and loosened first. The FZDB-1000 ton bag material loosening machine was developed to solve this problem. Adopting electronic remote control and hydraulic technology. It has the characteristics of simple structure, easy operation, and good extrusion effect.

usage method

Place the equipment flat in a certain position in the workshop (without the need for a foundation, with a ground bearing capacity of 5 tons per square meter), connect it to the power supply, and it can be used. Supporting equipment such as cranes or shovels.

This equipment undergoes strict debugging and pressure testing before leaving the factory, and must be filled with 46 # hydraulic oil before starting up.

Before starting up, connect the power supply according to the wiring diagram, using manual or remote control. The operator lifts the ton of raw materials with a shovel and places them on the middle platform between the two curved plates of the extruder. Press the remote control compression button, and the hydraulic cylinder slowly clamps the two curved plates. After loosening the material clamp, press the release button to slowly release the curved plate. If the clumping is not very severe, it can be done once. If the clumping is severe, the material can be turned 90 degrees (adjustable to any degree) and pressed again until the desired effect is achieved.

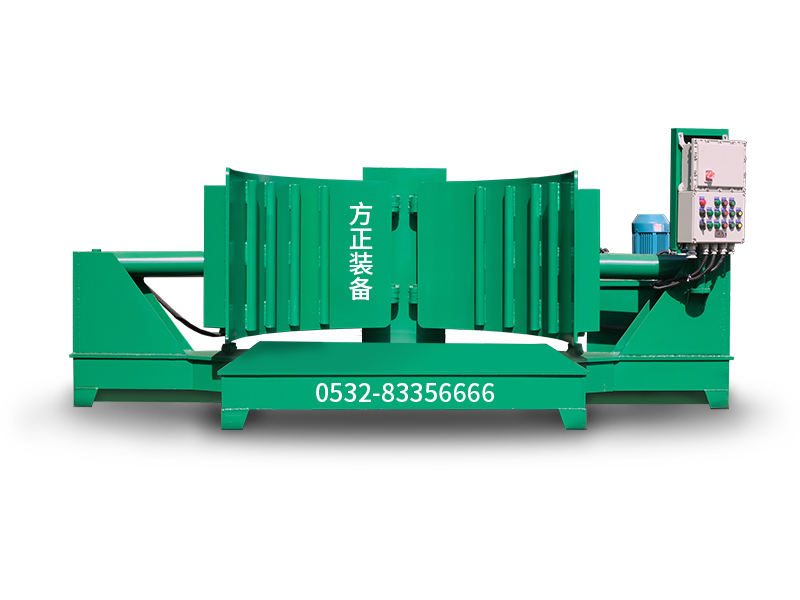

型号:

尺寸:4150*2050*1520mm

功率:12包/小时

效率:7.5KW

重量:3000KG

介绍:

随着复合肥生产电子计量配料的普及,原料供应商对氯化铵、磷酸铵采用吨包装越来越多,但吨包装原料结块后影响电子计量配料,必须先挤碎、疏松。FZDB-1000吨包物料松散机就是解决该问题而研发的。采用电子遥控、液压技术。具有结构简单、操作方便、挤压效果好的特点。

使用方法

将设备平放车间某一位置(不需做基础,地耐力每平方5吨即可),接上电源便可使用。配套设备吊机或铲车。

本设备出厂前经过严格调试、试压,开机前必须加满46#液压油。

开机前按照接线图接好电源,采用手控或遥控器控制,操作人员将吨包原料用铲车吊高放置挤压机两弧形板中间平台,按遥控压紧按钮,液压缸将两弧形板慢慢夹紧。物料夹松后,按放松按钮,弧形板慢慢松开。如果结块不十分严重一次即可。如果结块比较严重,可把物料转过90度(可调整任意度数),再压一次,直至达到效果。