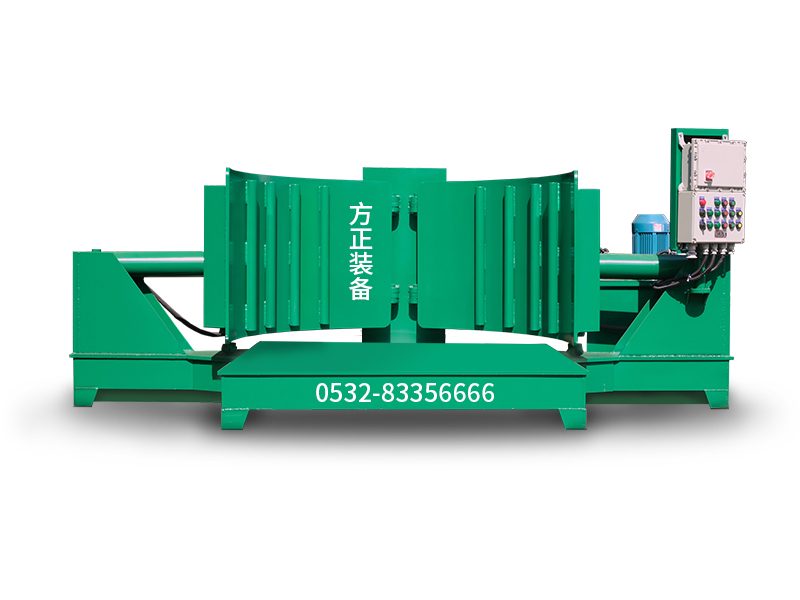

With the popularization of electronic metering ingredients in compound fertilizer production, raw material suppliers are increasingly using ton packaging for ammonium chloride and ammonium phosphate. However, the agglomeration of ton packaging raw materials affects electronic metering ingredients and must be crushed and loosened first. The FZDB-1000 ton bag material loosening machine was developed to solve this problem. Adopting electronic remote control and hydraulic technology. It has the characteristics of simple structure, easy operation, and good extrusion effect

model: FZDB1000-1

Size: 4150 * 2050 * 1520mm

Power: 12 packs/hour

Efficiency: 7.5KW

Weight: 3000KG

Introduction:

With the popularization of electronic metering ingredients in compound fertilizer production, raw material suppliers are increasingly using ton packaging for ammonium chloride and ammonium phosphate. However, the agglomeration of ton packaging raw materials affects electronic metering ingredients and must be crushed and loosened first. The FZDB-1000 ton bag material loosening machine was developed to solve this problem. Adopting electronic remote control and hydraulic technology. It has the characteristics of simple structure, easy operation, and good extrusion effect.

usage method

Place the equipment flat in a certain position in the workshop (without the need for a foundation, with a ground bearing capacity of 5 tons per square meter), connect it to the power supply, and it can be used. Supporting equipment such as cranes or shovels.

This equipment undergoes strict debugging and pressure testing before leaving the factory, and must be filled with 46 # hydraulic oil before starting up.

Before starting up, connect the power supply according to the wiring diagram, using manual or remote control. The operator lifts the ton of raw materials with a shovel and places them on the middle platform between the two curved plates of the extruder. Press the remote control compression button, and the hydraulic cylinder slowly clamps the two curved plates. After loosening the material clamp, press the release button to slowly release the curved plate. If the clumping is not very severe, it can be done once. If the clumping is severe, the material can be turned 90 degrees (adjustable to any degree) and pressed again until the desired effect is achieved.